Technology Research Institute

ACHROMAT Research Institute

ACHROMAT, equipped with excellent research personnel and

cutting-edge research facilities, conducts research on cores and

new alloy materials based on its proprietary

magnetic metal powder manufacturing technology.

cutting-edge research facilities, conducts research on cores and

new alloy materials based on its proprietary

magnetic metal powder manufacturing technology.

We develop high-efficiency, high-performance nickel-reduced and nickel-free core materials for power conversion devices,

reducing losses during power conversion, improving energy efficiency, and contributing to cost reduction of components.

In particular, through technological alliances and collaboration with the Korea Institute of Materials Science,

we are conducting high value-added research and developing materials capable of responding to the trend of increasing electrical frequencies.

reducing losses during power conversion, improving energy efficiency, and contributing to cost reduction of components.

In particular, through technological alliances and collaboration with the Korea Institute of Materials Science,

we are conducting high value-added research and developing materials capable of responding to the trend of increasing electrical frequencies.

Magnetic Powder Core Design Capability

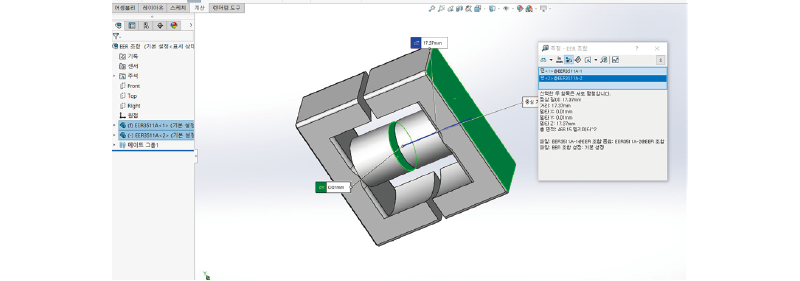

At the ACHROMAT Technology Research Institute, we design cores in-house, leveraging innovative molding technology and advanced powder engineering capabilities.

Powder Molding Machine

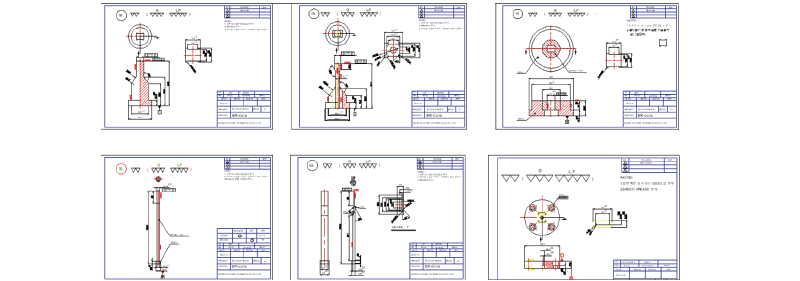

Mold Design Capability

Mold Design Capability

We possess advanced press mold design capabilities utilizing CAD software. Our expert design team carefully analyzes customer requirements to propose optimal design solutions, implement cost-saving measures, and ensure a fast development timeline.

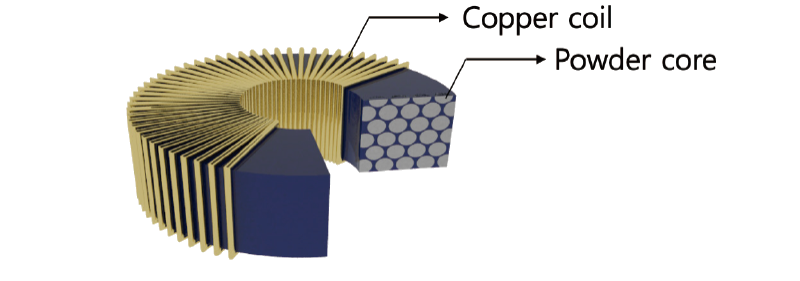

Electromagnetic Analysis and Optimization Technology

Based on Core Material and Shape

Based on Core Material and Shape

Utilizing 3D modeling, we create virtual inductors and conduct simulations for electromagnetic, thermal, and structural analysis. This allows us to predict core characteristics, heat generation, and evaluate mechanical strength.

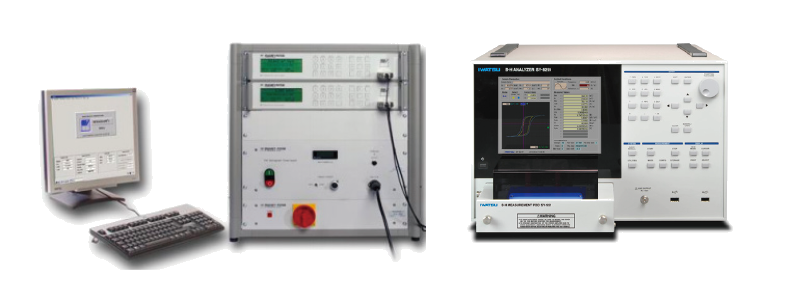

Powder Particle Characteristics and

Precision Electromagnetic Analysis for Cores/Inductors

Precision Electromagnetic Analysis for Cores/Inductors

We are equipped with state-of-the-art precision analysis equipment to evaluate the fundamental properties of powder-stage materials and conduct detailed electromagnetic analysis of cores and inductors. Backed by expert personnel and advanced technology, we ensure highly accurate analysis results.